ICYMI: Winter’s not done with us yet–which means salting, spreading, and plowing aren’t done with us yet either. Find out how John Langton’s crew at Langton Group in Woodstock, IL makes salt brine profitable.

The good, bad, and profit potential of liquids.

What many snow operators don’t realize is that they’re already using liquids in some way. When applying rock salt and pre-wetting or using treated salt, you are using liquids as an accelerant to speed up the melting process. Even when you are using just rock salt, you are still using liquids. Let me explain. You apply rock salt to a coating of snow, the rock salt uses the liquid in the snow to mix into a liquid salt brine, which then effectively lowers the freezing point, turning the snow into liquid! Now that we realize we all have experience using liquids at some level, let’s talk about what holds most contractors back from going all in.

Most people fear change. We get caught up in the “if it’s not broke don’t fix it” mentality. Here’s the problem with that: the system is broken. Applications of bulk rock salt are often more than what is needed to get the job done safely. Liquids can help with achieving lower application rates on both pre- and post-event treatments. Additionally, it can dramatically lower application rates on post treatments, even if you choose to apply bulk rock salt at that point. What holds most contractors back is slip and fall liability, capital expense, extra equipment, and most of all—lack of knowledge.

Trial & Error

My company, Langton Group, has been in business since 2005. In 2011, we tried several blended liquid products consisting of calcium blends, magnesium blends, and blends with organic sticking material, but never straight salt brine. We had some good and bad experiences but didn’t get much customer buy-in. The costs and application rates needed to achieve a profit—without charging more—wouldn’t align. We continued to slowly meander our way through, trying to figure them out.

In the summer of 2016, I went to a seminar for a manufacturer selling brine makers. That is when it all clicked: we should just be using straight salt brine! We went all-in and bought a brine maker and one SnowEx 300 gallon gps unit. We performed one route solely using salt brine for 34 out of the 36 snow events. We collected and measured a lot of data so we would know how to scale it in our company. The data measure consisted of the following:

- Air temperature

- Pavement temperature

- Water equivalent

- Type of precipitation

- Sun angle (time of season)

- Day or night

- Type of pavement

- Wind speed and direction

- Traffic load in parking lot

- Pictures right after application

- Pictures 24 hours after application

First, your cycle time to complete an application for an account or route may not meet your customer’s time constraints or level of service. Second, you gain a lot of indirect cost in drive time going to accounts and then back to refill. It eats into your profits. Finally, you lose account capacity for applying brine if you’re spending more time driving to accounts and refilling rather than actually applying brine at your customers’ sites.

I admit there were some events that were hard! We had to apply a lot of brine to get results as the air temperature was near 0 ̊ and pavement temperatures were in the single digits in the first year of the data gathering process. However, I knew it was important data to gather so we could develop our metrics and have confidence in our decision making. We were writing the script for post treating, sometimes without even plowing prior to applying brine.

The interesting part is we never told our customers we were changing. After the season, I spoke to the five customers on this route, which consisted of three banks, a small private road with medium traffic, and a small medical facility—all under one acre. I told them we used a different type of salt and asked if they noticed any differences. Three of the five customers told me they noticed no difference and the other two told me they felt both the building interior and parking lot were cleaner! I then explained that we switched from granular to liquid brine and asked if they would like to continue using brine or go back to the old way? All five customers said they would like to continue using brine. We have now been using brine at these accounts for the past six years!

Getting Started

How do you get started? It’s quite simple. You can either buy the salt brine or make it. Buying a salt brine maker will require more upfront capital and infrastructure, but will drive costs down. Partnering with your local salt brine supplier will allow you to ensure it’s the right fit, while not having the heavy capital investment up front.

Next, you’ll need to decide what truck to put a tank on and what type of equipment you would like to start with. Liquid application equipment consists of electric pumps, gas powered pumps, or hydraulic driven pumps. Most will have the option of a manual on/off switch to set the PSI, then you measure the ground speed, the width of the spray (to get the total square feet), and the amount of liquid coming out of the nozzles per minute to measure your application rate.

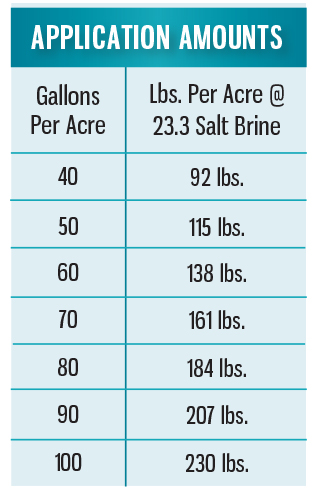

Personally, my recommendation for equipment is a gas-powered pump with GPS. The GPS allows precision with the amount of liquid brine you would like to apply per acre or lane mile. It’s up to you to determine the exact amounts in gallons that you will use per acre, but we’ve found the general rule of thumb is somewhere between 40 and 100 gallons

per acre depending on pretreatment or post-treatment and actual conditions. (See the Application Amounts graphic at right.)

Recovering Investment

The next question you may have is: how do I recover my capital investment? You’re really adding a whole new service line in pretreating prior to an event. You will also be able to save a significant amount of money and salt by post-treating, especially after plowing and pretreating using salt brine. Additionally, you are now offering a premium service that most contractors have yet to do a deep dive into, which gives you a competitive advantage. Just like in our current supply shortage, there is also a lower supply of contractors offering liquid applications; therefore, you can provide a better value and win more business at better profit margins!

![[VIDEO] Dickies®: Discover Workwear That’s Anything But Uniform](https://turfmagazine.com/wp-content/uploads/2023/06/1647663814-4b1a2a7742790a9b1e97a3b963477850192e1d6a9dfba9b07214a77bae25d6e3-d-218x150.jpg)

![[VIDEO] Dickies®: Discover Workwear That’s Anything But Uniform](https://turfmagazine.com/wp-content/uploads/2023/06/1647663814-4b1a2a7742790a9b1e97a3b963477850192e1d6a9dfba9b07214a77bae25d6e3-d-324x160.jpg)